SCREEN PRINTING 101: HOW DO WE DO IT?

Fairfax Screen Printing’s T-shirt Printing Process

Fairfax Screen Printing and Embroidery has been printing custom t-shirts and apparel for over thirty years and we know that great customer service is only part of the process. Creative and quality art, excellent screens and pre-press tools, and accurate high quality automatic printing are all part of the process that you don’t see.

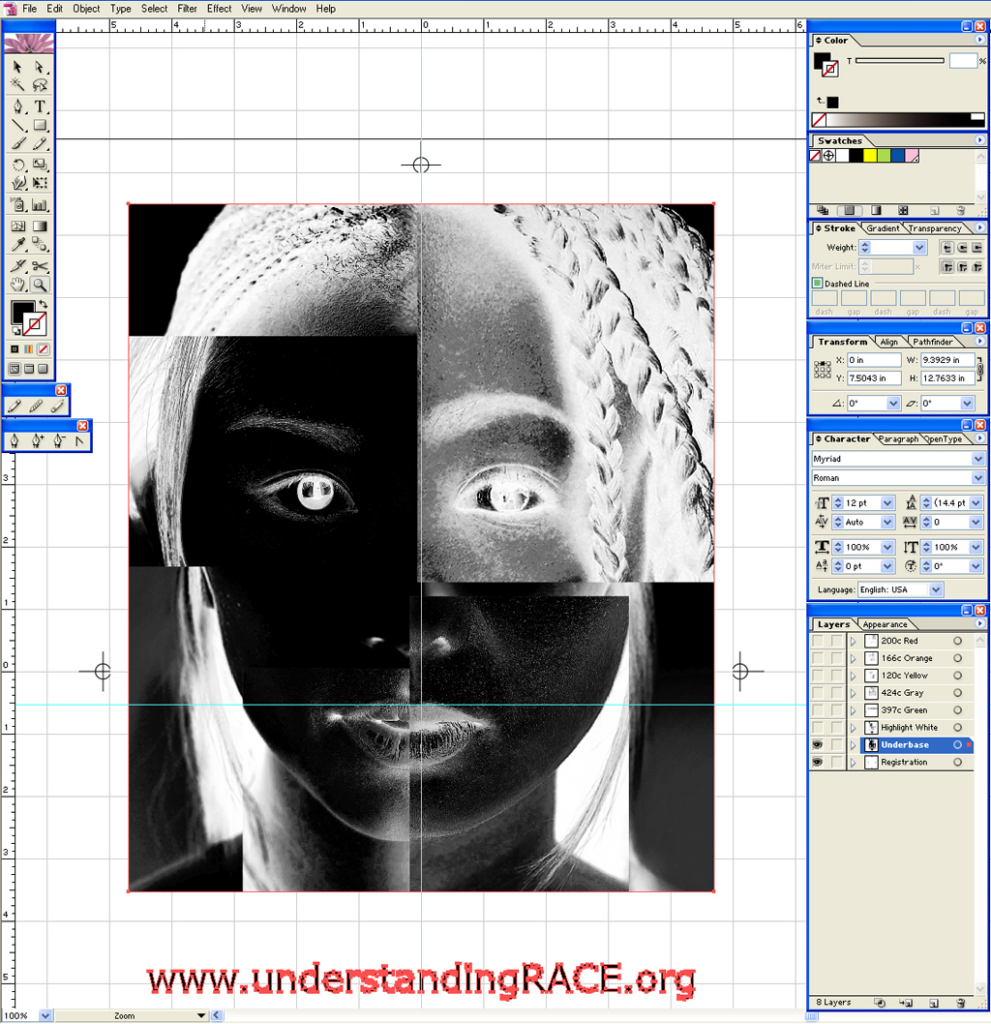

1. "CREATING THE DESIGN AND ART"

Quality art comes from a combination of good communication with you and our professional staff to transform your ideas into a good design. Share your ideas with us and we will create custom artwork for you. We then send you detailed proofs for your corrections, additions, or changes. Not until we have your final approval do we begin to print your custom t-shirts. We can transform the ordinary to the outstanding because we know the best design approach to produce great art and great custom t-shirts and apparel. This means exacting registration, consistent printing, and excellent color on your custom shirts.As part of creating embroidery art and before we embroider your order, we email you proofs of your design. We will work with you to refine and adjust your design until you feel it is right and we know it will come out beautifully.

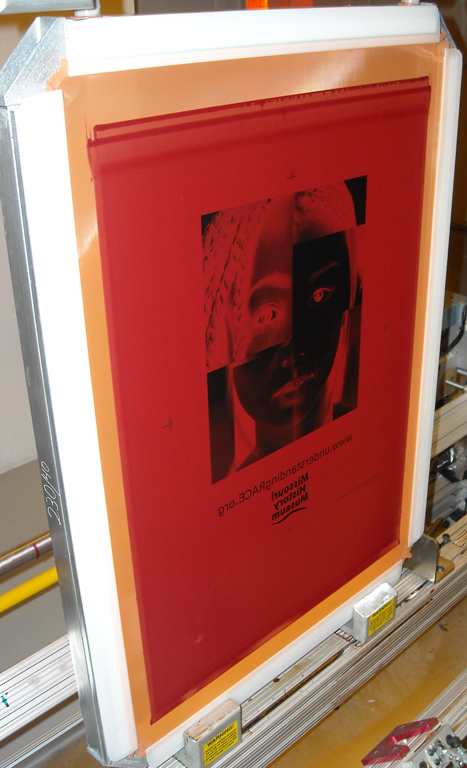

2. "SCREENS FOR YOUR IMPRINT ARE MADE"

Perfect Screens are the result of attention to detail combined with the latest methods for separating art into its various colors and delivering it to the screen. Today all art work is done on computers and color separations are created with the latest graphic software programs that separate each color in a design exactly and accurately. Our advanced equipment allows us to electronically transfer each color separation from the computer directly to the screen surface. The result is an extremely accurate reproduction of all fine details. This is essential for superior color separations, superior registration, and the making of screens that can hold the finest detail. Our art and screens can hold 2% dots compared to the industry standard of 10% dots on screens (especially import for simulated process printing). What this means to you is exceptional detail from the art work to the printing screen to the final print on your shirts.

Another aspect of superior screen making is how the photo sensitive emulsion used to make a screen is actually applied to the screens. At Fairfax Screen Printing photo sensitive emulsion is no longer applied by hand troughs as we have an automated system that applies emulsions to the screens. What this means for you is that the screen surface is extremely smooth with a consistently even application of the emulsion across the entire screen permitting the consistent application of ink to your garments across the entire surface of the design. We also utilize high tension screens which further improve not only registration and consistency but allow us to print sharp, bright, and vibrant colors on dark shirts giving excellent “hand”. It’s taken many years to grow our screen making to this exceptional level, but we believe the quality of our custom printed t-shirts to be second to none.

As part of creating embroidery art and before we embroider your order, we email you proofs of your design. We will work with you to refine and adjust your design until you feel it is right and we know it will come out beautifully.

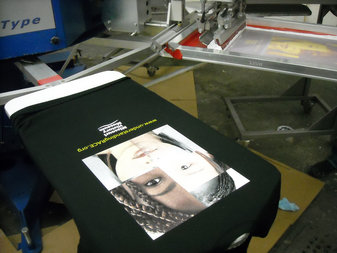

3. "PRINTING YOUR DESIGN ON GARMENTS"

The technology of art, art separations, and screen making has been outlined above. Now we need to turn to the issues of color and the actual printing process.

How do we get bright colors and expert color matching to meet the specifications of your art?

Fairfax Screen Printing has a computerized color mixing system that allows us to match all pantone colors as specified in any art work, and we do this at no extra cost to you. For corporate customers this means we can accurately match the specific PMS colors in your logos and other color sensitive applications. Even if you don’t have Pantone numbers, we can use the system to match almost any color you like.

Good color is easy to reproduce on white or light colored garments as they do not affect the color of inks, however, printing on dark colored garments presents one of the most difficult challenges in our business. To be successful a base of white ink that corresponds exactly to every detail of your design is initially applied to your garment, much like multiple coats of paint on a wall produce the truest color. After a white underbase each subsequent ink color is then imprinted over the white surface allowing the color to be both brilliant and pure. Areas of pure white in designs always receive a second layer of white ink to make it “pop”.

The final step is the actual printing of the garments. Screen printing is one of the oldest printing techniques known and was always done by hand in the past, in fact many screen printers still do most of their work by hand. Fairfax Screen Printing did all of its printing by hand until 1983 when we purchased our first automated four color printing machine (we were one of only two printers in the DC and Northern Virginia area to have automatic printers in the 1980’s). Over 2 decades later all our printing is now done on two high speed automated and totally computerized 10 color machines. They bear no resemblance to our first machine that today seems crude and awkward by comparison. Modern methods allow us to produce finely detailed images with beautiful brilliant colors and spot on registration time after time. Your screens are installed on our machines for accurate registration and the exact colored inks you have selected are loaded onto our screens and the printing begins. We are capable of producing 6000 garments a day and our prints are accurate and perfect. Lastly we use only the highest quality inks, the ones we have found after years of experience produce the best colors and the greatest durability.

Your printed shirts are then put into one of our dryers that heats the inks to 320+ degrees and transforms the inks from a liquid into a solid. While in the liquid form the inks penetrate the surface of the garments and as the ink goes from a liquid to a solid the ink actually permanently bonds with the fabric.

We monitor your order continuously through these steps ensuring garments of such quality that we guarantee them!

Quality custom t-shirt printing comes from our constant commitment to produce nothing but the highest quality screen printed t-shirts available. Our professional staff is trained to oversee and deliver nothing less. We pride ourselves on attention to detail and we continually seek out new technology. From computerized screen making, new and innovative ink systems, to high speed automated presses and drying equipment, we strive to ensure you recive nothing less than the best. Please feel free to visit our facility in Herndon, VA to see our samples of our top notch custom t-shirt printing.